Boosting European Logistics Performance with Rugged 3.5-Inch TFT LCD Displays

In the high-speed realm of logistics technology, where speed, accuracy, and resilience define the success of operations, one component often gets overlooked—the display screen. For manufacturers of barcode scanners, data collectors, and warehouse management terminals, selecting a reliable 3.5-inch LCD display is not a minor detail—it’s a decisive factor.

Across Europe—from the busy docks of Rotterdam to the automated fulfillment centers in Germany—logistics operators are upgrading their handheld systems with industrial-grade 3.5-inch TFT LCDs. These compact, lightweight screens provide the visual performance needed in rugged environments, ensuring both readability and device endurance.

Why 3.5-Inch LCDs Are the Go-To for Industrial Scanners

The 3.5-inch TFT LCD module strikes a perfect balance. It’s large enough to clearly display barcode scan confirmations, navigation menus, and status alerts, yet compact enough to fit into handheld, battery-powered devices.

Here are the essential advantages:

-

Optimal Screen Size

The 3.5-inch diagonal allows a full 320x240 QVGA resolution, which is ideal for both text and simple UI graphics. It enhances user feedback without overwhelming the form factor. -

Brightness & Contrast

Most 3.5-inch LCDs offer brightness levels between 300 to 500 nits, with anti-glare coatings, ensuring outdoor visibility under direct light—a common condition for last-mile logistics and dockside operations. -

Low Power Consumption

Designed with embedded systems in mind, these displays support energy-efficient backlighting, extending scanner battery life during long warehouse shifts. -

Wide Temperature Tolerance

With operating ranges from -20°C to +70°C, these LCDs suit refrigerated supply chains and high-temperature industrial sites. -

Durability

These modules can withstand vibration, shock, and even occasional drops, thanks to ruggedized mounting and protective coatings.

Application Scenarios in Europe

Let’s break down where these displays are making an impact:

1. Warehouse Barcode Scanners

European companies like DHL, DB Schenker, and DPD rely heavily on handheld barcode terminals. A 3.5-inch LCD in such devices helps workers verify scanned packages, read picking instructions, and confirm deliveries.

2. Inventory Management Tools

In retail warehouses and large grocery chains, portable scanners with 320x240 resolution LCDs support smart inventory operations—tracking thousands of SKUs with real-time updates.

3. Cold Chain Logistics

Frozen goods transporters in Northern Europe (especially Scandinavia) need screens that function even in sub-zero temperatures. TFT displays with extended temperature ratings meet this exact demand.

4. Shipping & Dockside Terminals

Logistics workers scanning container IDs in ports or outdoor yards benefit from sunlight-readable displays—a key feature of many 3.5-inch LCD modules.

Market Insight

According to a 2024 report by MarketsandMarkets, the European market for rugged handheld terminals is expected to grow at a CAGR of 7.2%, with display upgrades cited as a core driver. The increasing integration of 3.5-inch displays into smart logistics devices is expected to support this trend, especially in Germany, the UK, and the Netherlands.

Technical Breakdown: What Makes a Good 3.5-Inch TFT LCD Display for Industrial Use

To stand out in the competitive market of logistics terminals and barcode scanners, a 3.5-inch TFT LCD module must deliver not just basic display performance, but industrial-grade reliability. Let’s explore the technical features that define top-tier models:

1. Resolution & Pixel Structure

Most industrial barcode devices use a 320x240 (QVGA) or 480x320 (HVGA) resolution format. This ensures that text, numbers, and UI graphics are crisp and readable even in low-contrast environments such as warehouses or dim truck cabins.

-

QVGA (320x240): Ideal for basic barcode info, order status, and device settings.

-

HVGA (480x320): Allows for additional UI features like navigation, menus, and even battery status icons.

2. Viewing Angles

A wide viewing angle—typically 160° or more—is crucial in mobile terminals. Whether the scanner is tilted during use or being read from a side position, the display must retain clarity and color consistency.

Modern TFT LCDs use IPS or TN+Film technologies to improve visibility from all angles, ensuring no operational delays caused by misread screens.

3. Interface Options

To support embedded integration, 3.5-inch LCDs often come with versatile interfaces such as:

-

SPI: For simple MCU-controlled devices

-

RGB: For ARM-based SoCs with higher throughput

-

MCU Parallel (8-bit/16-bit): For legacy barcode scanner platforms

This flexibility ensures fast integration into OEM barcode devices, reducing development time for system manufacturers.

4. Touch Panel Compatibility

Many 3.5-inch LCDs are bundled with resistive or capacitive touch panels, depending on the target application:

-

Resistive touch: More suitable for warehouse gloves and cold environments

-

Capacitive touch: Preferred for modern cleanroom logistics or retail back-office settings

TFT vs. OLED vs. E-Ink: Why TFT Still Wins in Logistics

With the rise of new display technologies, why does TFT LCD still dominate industrial handheld use?

| Feature | TFT LCD | OLED | E-Ink |

|---|---|---|---|

| Brightness | High (300–500 nits) | Medium (but degrades) | Low (reflective only) |

| Outdoor Visibility | Excellent (with coating) | Poor (fades in sunlight) | Good, but no backlight |

| Touch Support | Wide (resistive/capacitive) | Capacitive only | Limited |

| Cost | Cost-effective | High | High |

| Response Time | Fast (<20ms) | Fast | Very slow |

Clearly, 3.5-inch TFT displays are still the most balanced and cost-effective solution for logistics applications.

Common Barcode Scanner Use Cases Across Europe

Parcel Delivery Terminals

Used by logistics drivers across France and Germany, these devices rely on a 3.5-inch screen to:

-

Show delivery address & route

-

Display barcode scan confirmation

-

Let driver collect digital signatures

These screens often need to handle outdoor lighting, long working hours, and drop tests from 1m height.

Warehouse Management Consoles

From Poland to Spain, large fulfillment centers use handheld warehouse terminals for real-time location tracking of goods.

The 3.5-inch TFT LCD in these terminals helps:

-

Display storage bin locations

-

Verify picked items against order lists

-

Reduce picking errors through visual cues

Cold Chain Monitoring Devices

Scanners operating inside frozen trucks or refrigerated sections need LCDs that work from -20°C to 70°C. TFT displays with high contrast remain readable even under foggy or frosted conditions.

Europe’s Demand for 3.5-Inch LCDs: Country-by-Country Breakdown

European logistics manufacturers are increasingly turning to 3.5-inch LCD modules as a core component in barcode scanners, handheld data terminals, and portable verification devices. Let’s explore the specific market behaviors across the region.

Home

Home HEM LCD

HEM LCD  Jun 07,2025

Jun 07,2025

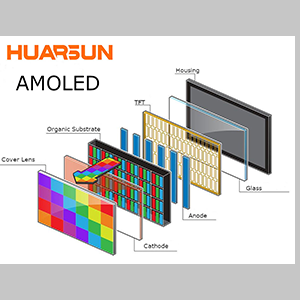

Why Smart Glasses Skip Screens – But Small TFT and AMOLED Modules Thrive

Why Smart Glasses Skip Screens – But Small TFT and AMOLED Modules Thrive

Sep 08,2022

Sep 08,2022